- Black Friday! 35% Off

- Free carbon neutral shipping on US orders

End of Time:

:

:

:

0

0 items

0.00₦

No products in the cart.

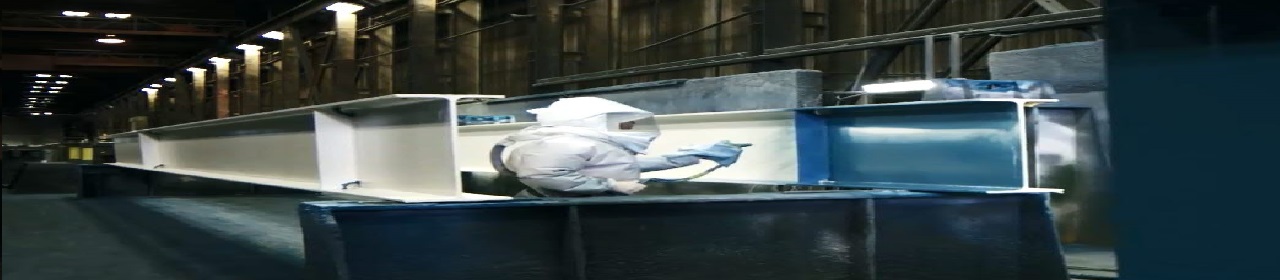

Sigma paints is one of the most reliable protective coating systems and state-of-the-art marine coatings which are both durable and environmentally friendly without sacrificing quality or dependability on the market. Sigma paints products are specialized paints and coatings for

construction, marine, oil and gas and industrial applications. Sigma paints are available in several qualities and specific shades.

The solvent-based products are made from soybean oil rather than petroleum-based raw materials.

There are four categories of specialized coatings by sigma paints which include:

Anti-corrosives

Low VOC paints

FDA approved food safe epoxy

Rust inhibitors

However, there are different types of sigma paints and they are;

The antifouling paint is used for the protection of submerged surfaces such as ship hulls, offshore installations, pilings and other marine structures.

Epoxy Primer is used for corrosion control of a range of substrates such as steel, aluminium and GRP.

Epoxy Topcoat is used for topcoats on oil tankers, dry cargo vessels and fuel tanks.

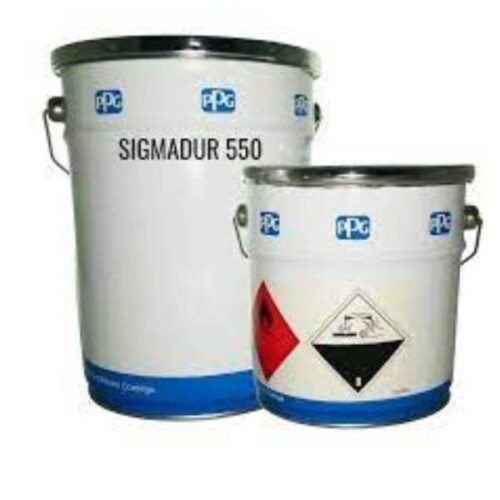

Polyurethane Topcoat has excellent UV resistance, gloss retention and colour stability over a long service life. It can also be applied at low temperatures.

Polyurethane Intermediates consist of two components – Hardener (Part A) and Paint (Part B). They are both used for coating and anti-corrosion purposes.

All sigma paints products can be used for marine and industrial paints and protective coatings.

The marine categories can be used for a wide range of coating requirements for new builds and dry-dock maintenance. The offshore categories of paints can be used by oil and gas industries for surface treatment materials that meet stringent performance requirements. Other categories of sigma paint products can be used extensively in heavy construction and power generation projects.

To be more specific, generally, sigma paints are very useful in painting, waterproofing, and anti-corrosive materials. Sigma Paints products are basically used for a wide range of applications including:

Concrete waterproofing

Water tank lining to prevent leakage

Anti-corrosion coating on steel structures

Exterior waterproof coatings

Protective coatings on vessels, pipelines and tanks.

Companies in a wide variety of industries can trust any of the sigma paints with their specific needs. Whether you are painting one small part; or an entire industrial facility, sigma paints can meet your requirements. Morven Industrial Limited is a leading engineering, procurement and construction company. We supply all kinds of engineering and construction products to industries. We have stocked up all types of sigma paints. As one of the leading manufacturers in the paint and coating industry, these products are of superior quality and are cost-effective. Contact us now for your supply.

The solvent-based products are made from soybean oil rather than petroleum-based raw materials.

There are four categories of specialized coatings by sigma paints which include:

Anti-corrosives

Low VOC paints

FDA approved food safe epoxy

Rust inhibitors

However, there are different types of sigma paints and they are;

The antifouling paint is used for the protection of submerged surfaces such as ship hulls, offshore installations, pilings and other marine structures.

Epoxy Primer is used for corrosion control of a range of substrates such as steel, aluminium and GRP.

Epoxy Topcoat is used for topcoats on oil tankers, dry cargo vessels and fuel tanks.

Polyurethane Topcoat has excellent UV resistance, gloss retention and colour stability over a long service life. It can also be applied at low temperatures.

Polyurethane Intermediates consist of two components – Hardener (Part A) and Paint (Part B). They are both used for coating and anti-corrosion purposes.

All sigma paints products can be used for marine and industrial paints and protective coatings.

The marine categories can be used for a wide range of coating requirements for new builds and dry-dock maintenance. The offshore categories of paints can be used by oil and gas industries for surface treatment materials that meet stringent performance requirements. Other categories of sigma paint products can be used extensively in heavy construction and power generation projects.

To be more specific, generally, sigma paints are very useful in painting, waterproofing, and anti-corrosive materials. Sigma Paints products are basically used for a wide range of applications including:

Concrete waterproofing

Water tank lining to prevent leakage

Anti-corrosion coating on steel structures

Exterior waterproof coatings

Protective coatings on vessels, pipelines and tanks.

Companies in a wide variety of industries can trust any of the sigma paints with their specific needs. Whether you are painting one small part; or an entire industrial facility, sigma paints can meet your requirements. Morven Industrial Limited is a leading engineering, procurement and construction company. We supply all kinds of engineering and construction products to industries. We have stocked up all types of sigma paints. As one of the leading manufacturers in the paint and coating industry, these products are of superior quality and are cost-effective. Contact us now for your supply.

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

SigmaCover 350, a two-component, high-build polyamide cured anticorrosive epoxy primer/coating for wide use in Marine and Protective Coatings such as topsides, decks, superstructures and cargo holds. The fast-curing primer can be used on concrete and steel, with good impact and abrasion resistance and excellent corrosion resistance, applied by spray, brush or roller.

Read more

Add to Wishlist

Add to Wishlist

PPG SigmaCover 280 is a universal epoxy anticorrosive primer based upon pure epoxy technology. It is suitable for ballast tanks, decks, and topside, superstructure, hull and cargo oil tanks. SigmaCover 280 is used in protective coating systems for steel and non-ferrous metals, curing at temperatures down to 5°C (41°F), and can be overcoated with most alkyd, chlorinated rubber, vinyl, epoxy and two-component polyurethane coatings.

Read more

Add to Wishlist

Add to Wishlist

Product categories

All Categories

Need Help?

09129659392 / 08144536538

Monday – Friday: 9:00-20:00

Saturady: 11:00 – 15:00

Customer Service

Copyright 2024 © Morven Industrial All right reserved. By Sort Odds Global Solutions