- Black Friday! 35% Off

- Free carbon neutral shipping on US orders

0.00₦

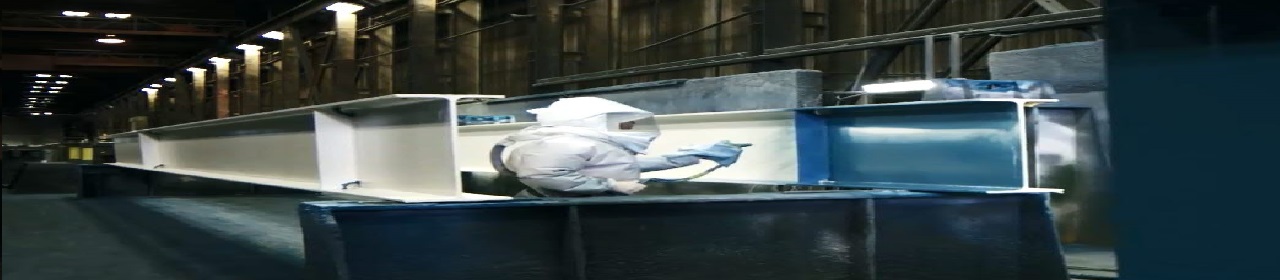

Morven Industrial Ltd is supplier of all Coating products, consumables, equipment and tools. Our job is to protect the assets of our clients. Protective coatings are used on most metal substrates to protect against corrosion due to environmental influences such as weathering,

Protective coating of wood surfaces (including waterborne).There are two forms of coating materials which are powder coating and wet paint coating. Resins, additives, and pigments are all included in both coatings. The main difference is that wet paint contains solvent, whereas powder coating does not. All of the other components of wet paint are suspended in liquid form due to the solvent. Powder coating, on the other hand, is applied as a dry powder.

The powder coating is a kind of coating that involves a free-flowing, dry powder. It is a dry finishing process, unlike the traditional wet paint process. Powder coating is applied electrostatically and then heated to cure. The powder must contain the appropriate pigments, binders and additives to be able to achieve the desired result. Powder coating typically has superior wear and corrosion resistance compared to most paint processes.

Powder coatings can be used on various substrates such as steel, aluminium, copper or zinc alloy. It can also be used on plastics such as polyester, acrylics or PVC with great results too. The colour range is virtually limitless.

The waterproof coating is another form of coating but especially for concrete. It is an effective method to prevent the penetration of moisture, water and salts into concrete structures while protecting against staining caused by environmental influences. It also significantly prolongs the service life of concrete structures such as patios, terraces and driveways.

The four components of coatings are:

Pigment: Which determines the colour, and dries to become a sub coat or basecoat.

Binder: Which holds the filler and pigment together and must be compatible with the type of coating.

Filler/Additives: It takes up space between the pigments or binders (in some epoxy paints) to give a smooth surface (solidified by hardeners).

Solvents: These are chemicals added to a binder to reduce the viscosity and make it easier to apply to a substrate.

At Morven Industrial, we have close partnerships with many different paint manufacturers to ensure that we always supply quality paints and coating products. We can supply any type of painting and coating materials in whatever quantity. Visit our catalogue to select your desired product.

Product categories

All Categories

Need Help?

Monday – Friday: 9:00-20:00

Saturady: 11:00 – 15:00

Customer Service

Copyright 2024 © Morven Industrial All right reserved. By Sort Odds Global Solutions